Year

2012Abstract

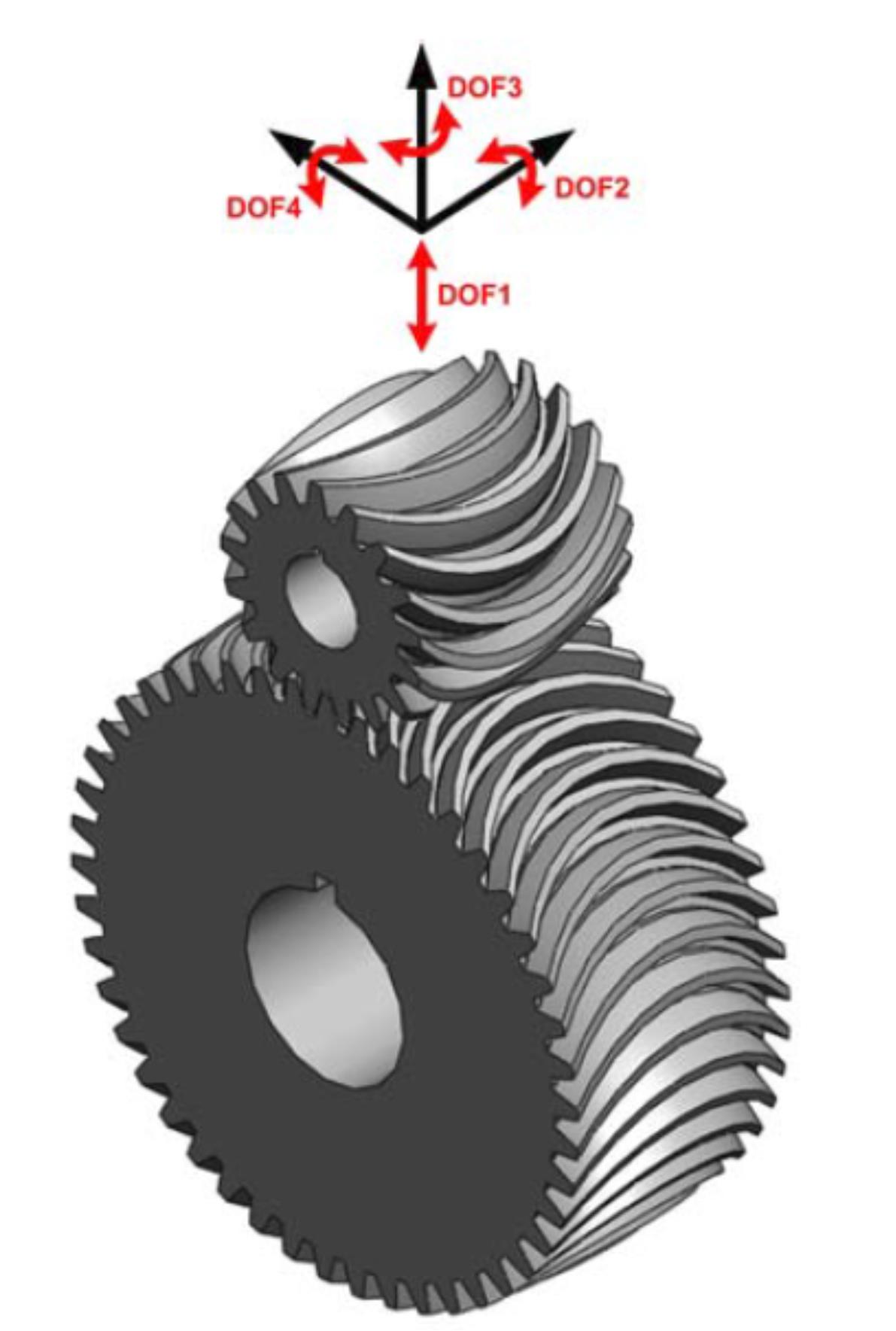

The family of cylindrical parallel-axis involute gearing currently include spur, helical and double-helical gears, all having straight tooth traces in the developed pitch plane. However, gears with curved tooth traces have also been proposed. One of the obvious merits of this configuration is the insensitivity to shaft misalignment. Although this and other merits of gears with lengthwise curved teeth (C-gears) were highlighted, they have never been mass-manufactured. Many types and shapes of C-gears have been envisioned, a dozen or so, but the particular merits and demerits of each type were never put together in a comparative study aiming at stipulating which type of gear can be manufactured simplest of all or which type is most appropriate for use in specific applications. In this paper, a comprehensive comparative study is carried out for all C-gear types in the repertoire. Finally, the promising ones are singled out for detailed scrutiny; and prospective applications are pointed out for these types.