Year

2020Abstract

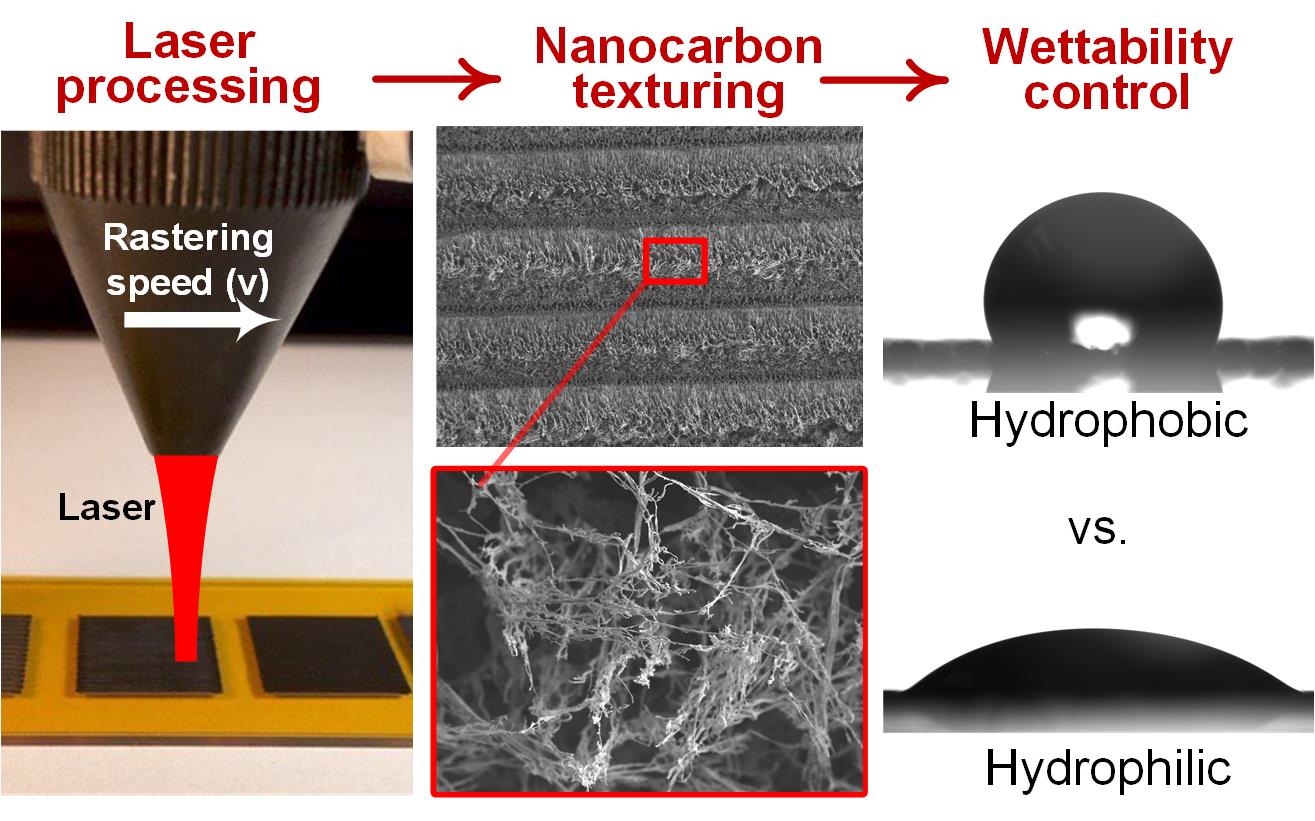

The growth of laser-induced nanocarbons, referred to here as LINC for short, directly on polymeric surfaces is a promising route toward surface engineering of commercial polymers. This paper aims to demonstrate how this new approach can enable achieving varied surface properties based on tuning the nanostructured morphology of the formed graphitic material on commercial polyimide (Kapton) films. We elucidate the effects of tuning laser processing parameters on the achieved nanoscale morphology and the resulting surface hydrophobicity or hydrophilicity. Our results show that by varying lasing power, rastering speed, laser spot size, and line-to-line gap sizes, a wide range of water contact angles are possible, i.e. from below 20° to above 110°. Combining water contact angle measurements from an optical tensiometer with LINC surface characterization using optical microscopy, electron microscopy, and Raman spectroscopy enables building the process-structure-property relationship. Our findings reveal that both the value of contact angle and the anisotropic wetting behavior of LINC on polyimide are dependent on their hierarchical surface nanostructure which ranges from isotropic nanoporous morphology to fibrous morphology. Results also show that increasing gap sizes lead to an increase in contact angles and thus an increase in the hydrophobicity of the surface. Hence, our work highlight the potential of this approach for manufacturing flexible devices with tailored surfaces.