Year

2013Volume

7Issue

4Pages

3565–3580Abstract

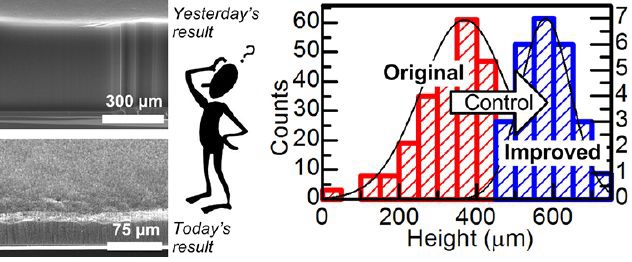

While many promising applications have been demonstrated for vertically aligned carbon nanotube (CNT) forests, lack of consistency in results (e.g., CNT quality, height, and density) continues to hinder knowledge transfer and commercialization. For example, it is well known that CNT growth can be influenced by small concentrations of water vapor, carbon deposits on the reactor wall, and experiment-to-experiment variations in pressure within the reaction chamber. However, even when these parameters are controlled during synthesis, we found that variations in ambient lab conditions can overwhelm attempts to perform parametric optimization studies. We established a standard growth procedure, including the chemical vapor deposition (CVD) recipe, while we varied other variables related to the furnace configuration and experimental procedure. Statistical analysis of 280 samples showed that ambient humidity, barometric pressure, and sample position in the CVD furnace contribute significantly to experiment-to-experiment variation.We investigated how these factors lead to CNT growth variation and recommend practices to improve process repeatability. Initial results using this approach reduced run-to-run variation in CNT forest height and density by more than 50%.