Year

2021Abstract

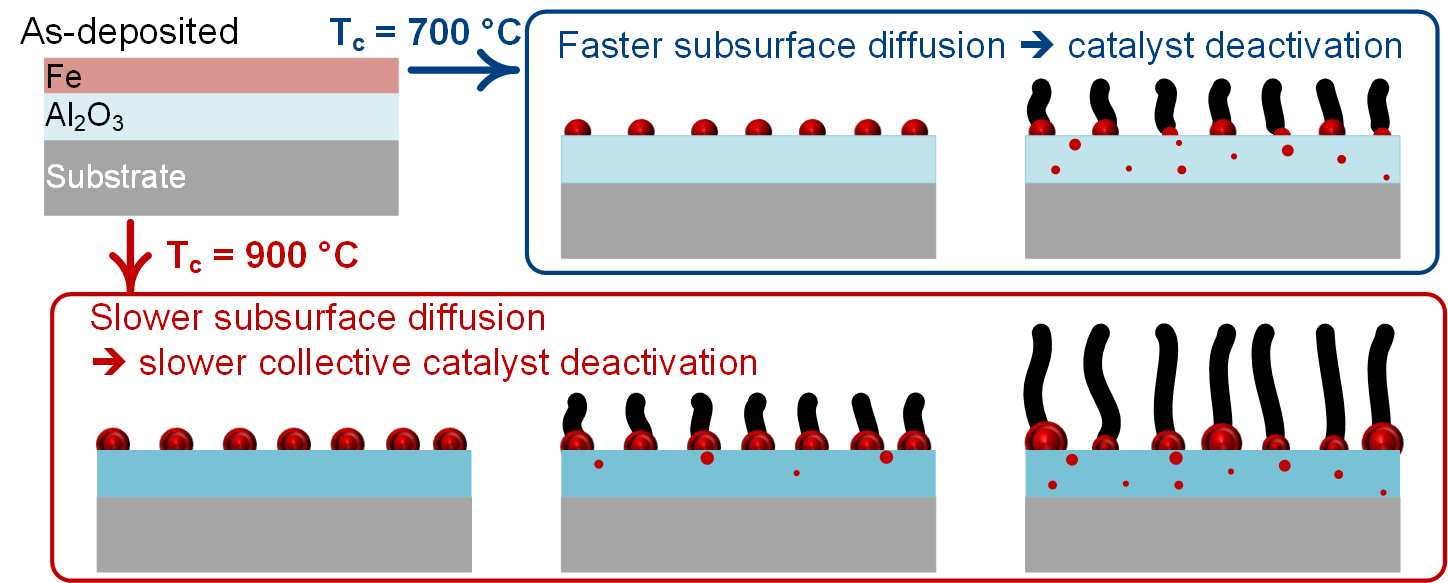

In this paper, we present an approach for boosting the catalytic lifetime in the growth of carbon nanotubes (CNTs) by chemical vapor deposition from an oxide-supported metal catalyst. We leverage a rapid thermal pretreatment to decouple the catalyst nanoparticle formation step, by solid-state dewetting, from the catalytic activation and CNT growth step. We find that the CNT yield significantly increased with the increasing catalyst formation temperature. To reveal the mechanism, we combined real-time kinetics measurements with a comprehensive characterization of the catalyst and support films after annealing in a reducing environment. Our results reveal that the observed threefold boost in CNT growth at higher catalyst formation temperatures results from an increased catalytic lifetime rather than an increased reaction rate. Atomic force microscopy analysis of the catalyst nanoparticles revealed that the loss of the catalyst by subsurface diffusion was suppressed, which delayed catalyst deactivation. The properties of the alumina film after annealing at different temperatures were analyzed by ellipsometry, nanoindentation, X-ray diffraction, and contact angle measurement. We show that annealing at 900 °C in hydrogen results in denser and less porous alumina than lower temperature annealing. Both film crystallinity and Lewis basicity also increased with a higher annealing temperature, highlighting the capability of our approach to tune the catalytic performance by tailoring the oxide support via a single thermochemical pretreatment step. Hence, this decoupled process can enable the growth of longer CNTs that is not achievable by conventional coupled recipes.