Year

2018Abstract

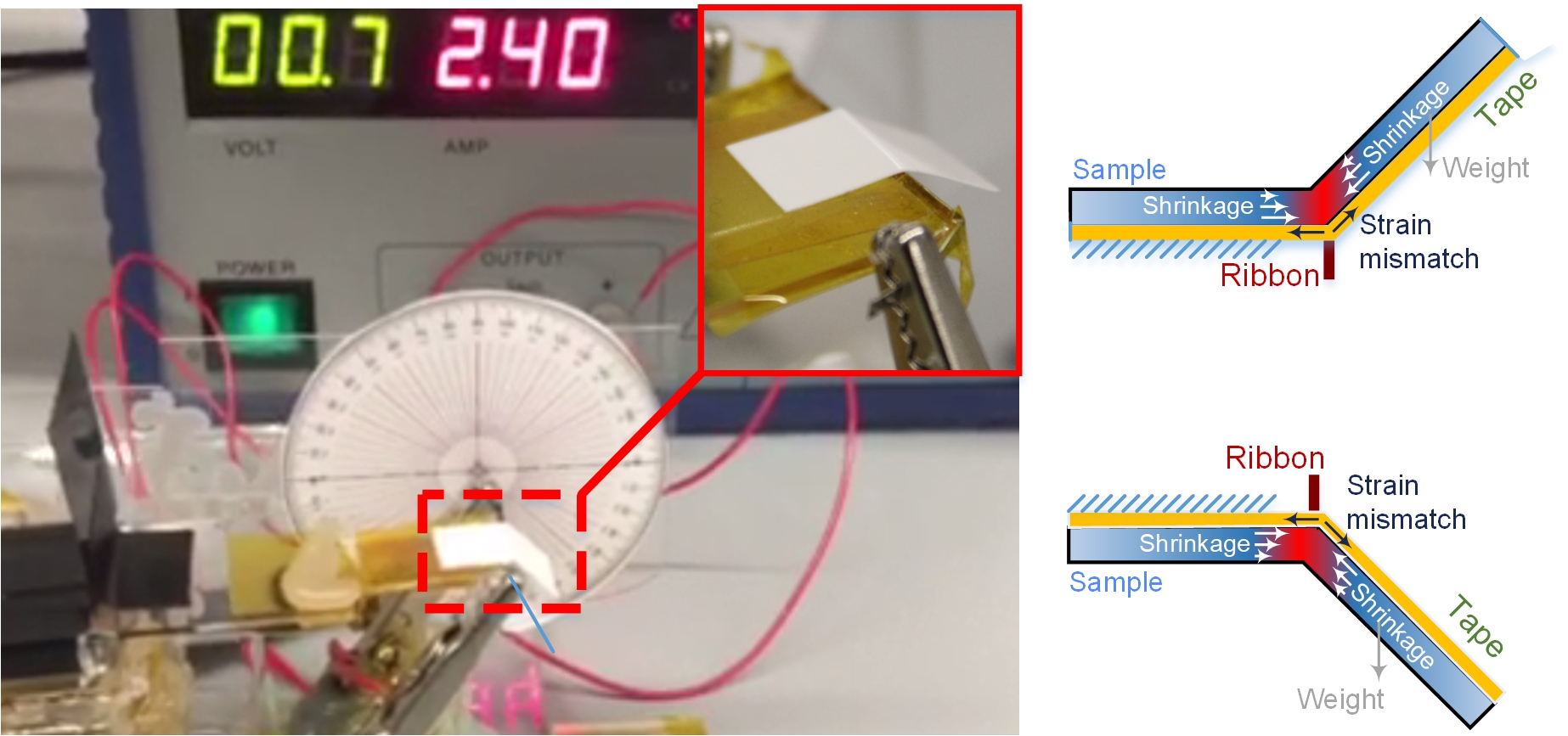

The purpose of this paper is to characterize the kinetics and direction of self-folding of pre-strained polystyrene (PSPS) and non-pre-strained styrene (NPS), which results from local shrinkage using a Origamiresistively heated ribbon in contact with the polymer sheet. A temperature gradient across the thickness of this shape memory polymer (SMP) sheet induces folding along the line of contact with the heating ribbon. Varying the electric current changes the degree of folding and extent of local material flow. This method can be used to create practical 3D structures. Sheets of PSPS and NPS were cut to 10 × 20 mm samples and their folding angles were plotted with respect to time, as obtained from in situ videography. In addition, the use of polyimide tape (Kapton) was investigated for controlling the direction of self-folding. Results show that folding happens on the opposite side of the sample with respect to the tape, regardless of which side the heating ribbon is on, or whether gravity is opposing the folding direction. Given the tunability of fold times and extent of local material flow, heat-assisted folding is a promising approach for manufacturing complex 3D lightweight structures by origami engineering.