Year

2019Abstract

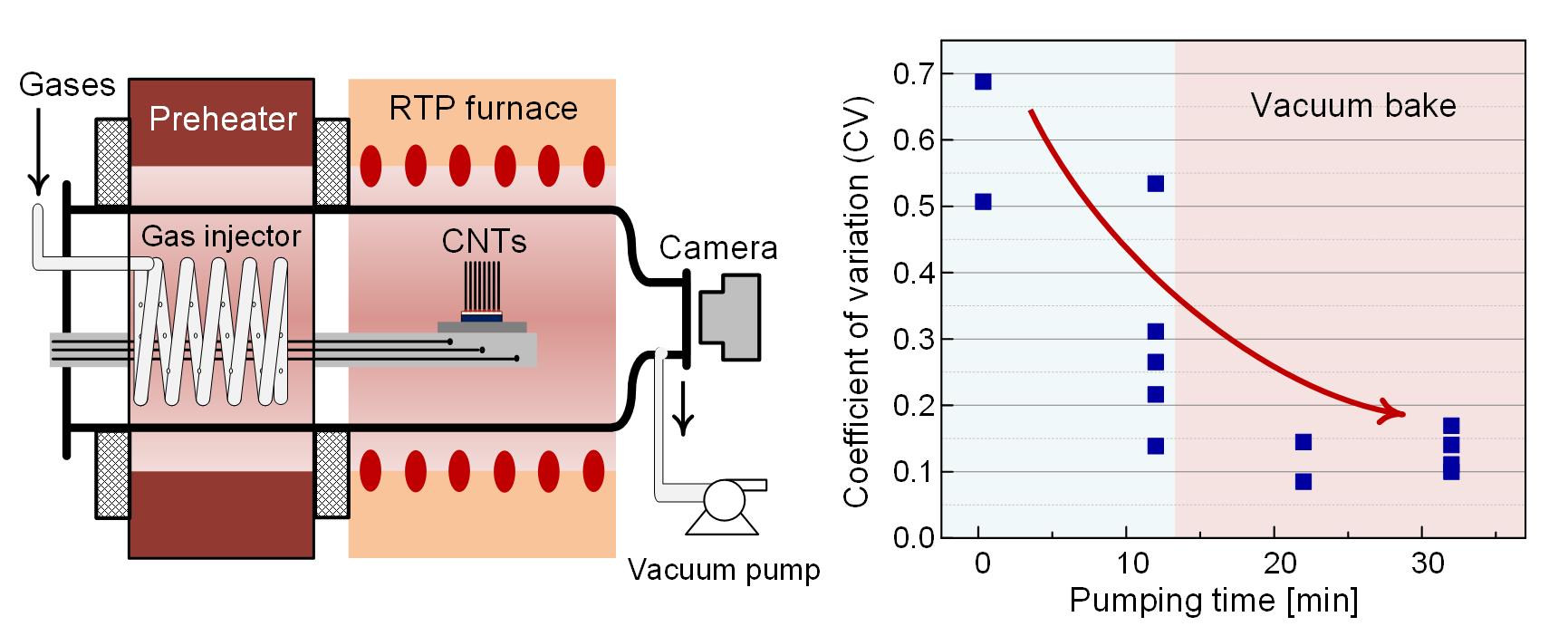

The root causes underlying run-to-run variations in the synthesis of vertically aligned carbon nanotubes (VACNTs) by chemical vapor deposition can be attributed to the sensitivity of the process to small uncontrolled/unmeasured quantities of gaseous species in the reactor. Hence, universally applicable processing steps are needed to ensure consistency. Here, we quantitatively test the effectiveness of various processing heuristics in reducing growth variability. Statistical analysis of 95 VACNT samples grown by 11 different recipes demonstrated that pumping with mild baking at 200 °C prior to catalyst formation resulted in significantly reduced coefficient of variation of forest heights (by a factor of 6). In contrast, other processing steps such as vacuum pumping without heating and adjusting He to H2 ratio during catalyst formation did not significantly affect growth variability; we could not reject the null hypothesis at any reasonable level of significance. Atomic force microscopy analyses suggest that variability in VACNT height is not caused by variations of nanoparticle size distribution, thus we can conjecture that the variability might be caused by variations in the chemical state of catalyst nanoparticles.