Year

2012Volume

83Issue

1Pages

15104–15113Abstract

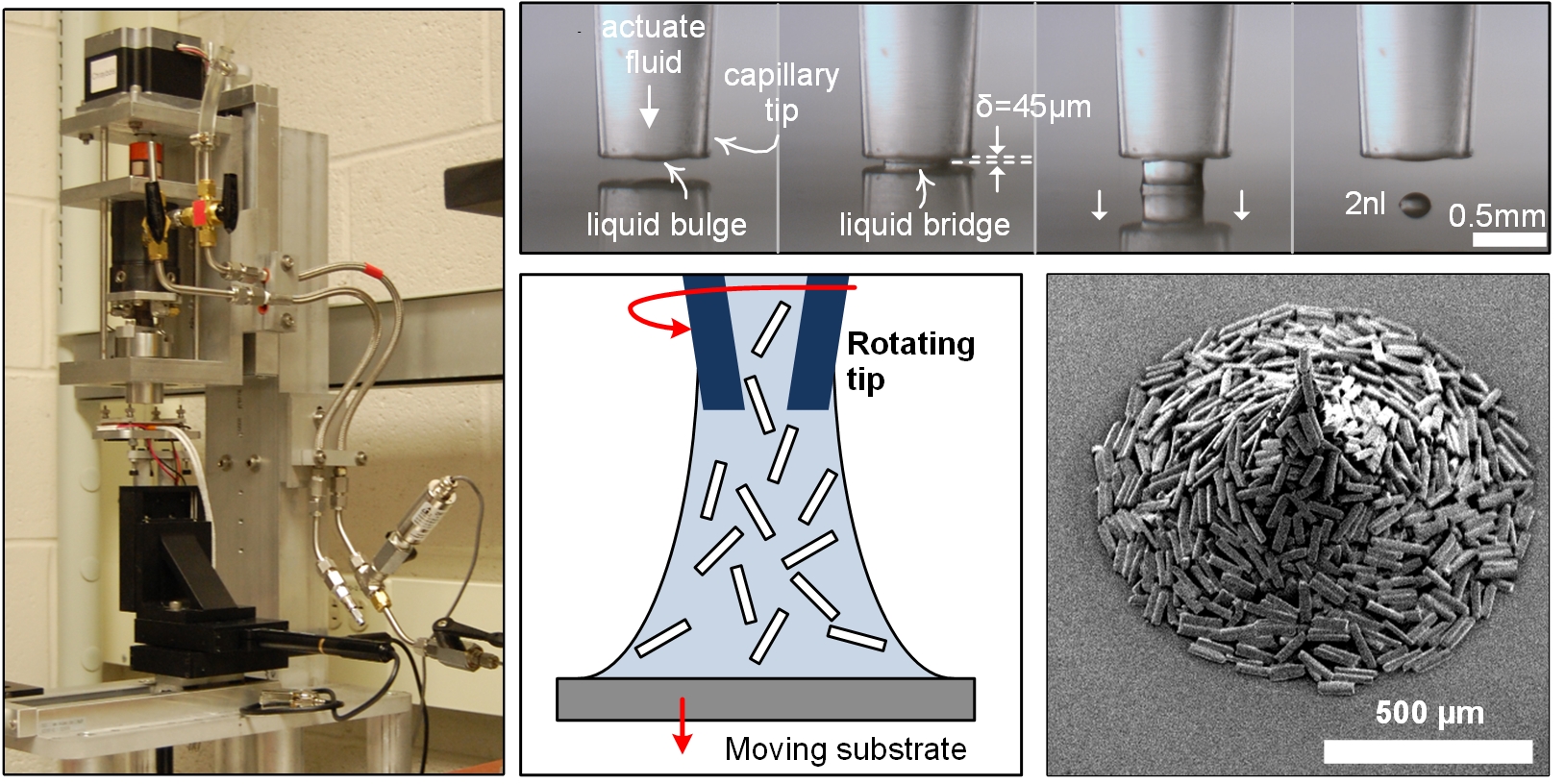

Capillary forces provide a ubiquitous means of organizing micro- and nanoscale structures on substrates. In order to investigate the mechanism of capillary self-assembly and to fabricate complex ordered structures, precise control of the meniscus shape is needed. We present a precision instrument that enables deposition of liquid droplets spanning from 2 nl to 300 μl, in concert with mechanical manipulation of the liquid-substrate interface with four degrees of freedom. The substrate has sub-100 nm positioning resolution in three axes of translation, and its temperature is controlled using thermoelectric modules. The capillary tip can rotate about the vertical axis while simultaneously dispensing liquid onto the substrate. Liquid is displaced using a custom bidirectional diaphragm pump, in which an elastic membrane is hydraulically actuated by a stainless steel syringe. The syringe is driven by a piezoelectric actuator, enabling nanoliter volume and rate control. A quantitative model of the liquid dispenser is verified experimentally, and suggests that compressibility in the hydraulic line deamplifies the syringe stroke, enabling sub-nanoliter resolution control of liquid displacement at the capillary tip. We use this system to contact-print water and oil droplets by mechanical manipulation of a liquid bridge between the capillary and the substrate. Finally, we study the effect of droplet volume and substrate temperature on the evaporative self-assembly of monodisperse polymer microspheres from sessile droplets, and demonstrate the formation of 3D chiral assemblies of micro-rods by rotation of the capillary tip during evaporative assembly.