Year

2020Abstract

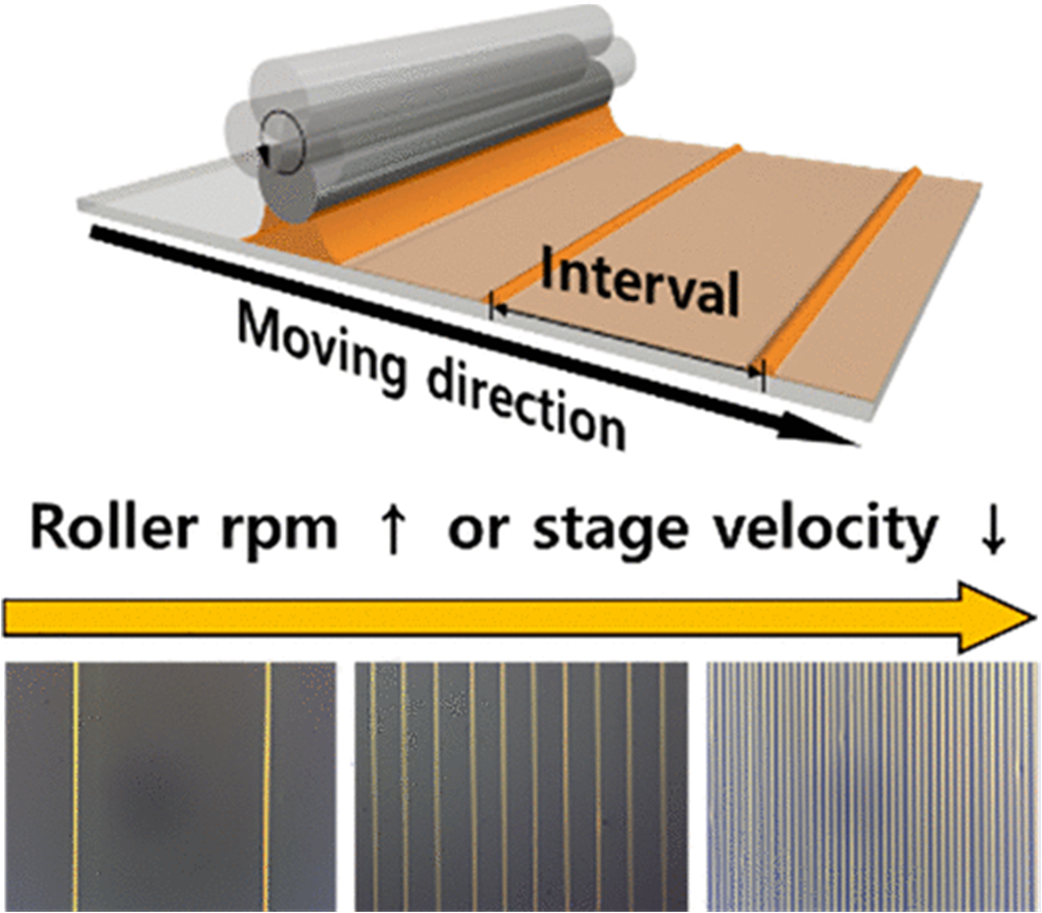

Evaporative self-assembly of semiconducting polymers is a low-cost route to fabricating micrometer and nanoscale features for use in organic and flexible electronic devices. However, in most cases, rate is limited by the kinetics of solvent evaporation, and it is challenging to achieve uniformity over length- and time-scales that are compelling for manufacturing scale-up. In this study, we report high-throughput, continuous printing of poly(3-hexylthiophene) (P3HT) by a modified doctor blading technique with oscillatory meniscus motion—meniscus-oscillated self-assembly (MOSA), which forms P3HT features ∼100 times faster than previously reported techniques. The meniscus is pinned to a roller, and the oscillatory meniscus motion of the roller generates repetitive cycles of contact-line formation and subsequent slip. The printed P3HT lines demonstrate reproducible and tailorable structures: nanometer scale thickness, micrometer scale width, submillimeter pattern intervals, and millimeter-to-centimeter scale coverage with highly defined boundaries. The line width as well as interval of P3HT patterns can be independently controlled by varying the polymer concentration levels and the rotation rate of the roller. Furthermore, grazing incidence wide-angle X-ray scattering (GIWAXS) reveals that this dynamic meniscus control technique dramatically enhances the crystallinity of P3HT. The MOSA process can potentially be applied to other geometries, and to a wide range of solution-based precursors, and therefore will develop for practical applications in printed electronics.