Year

2016Abstract

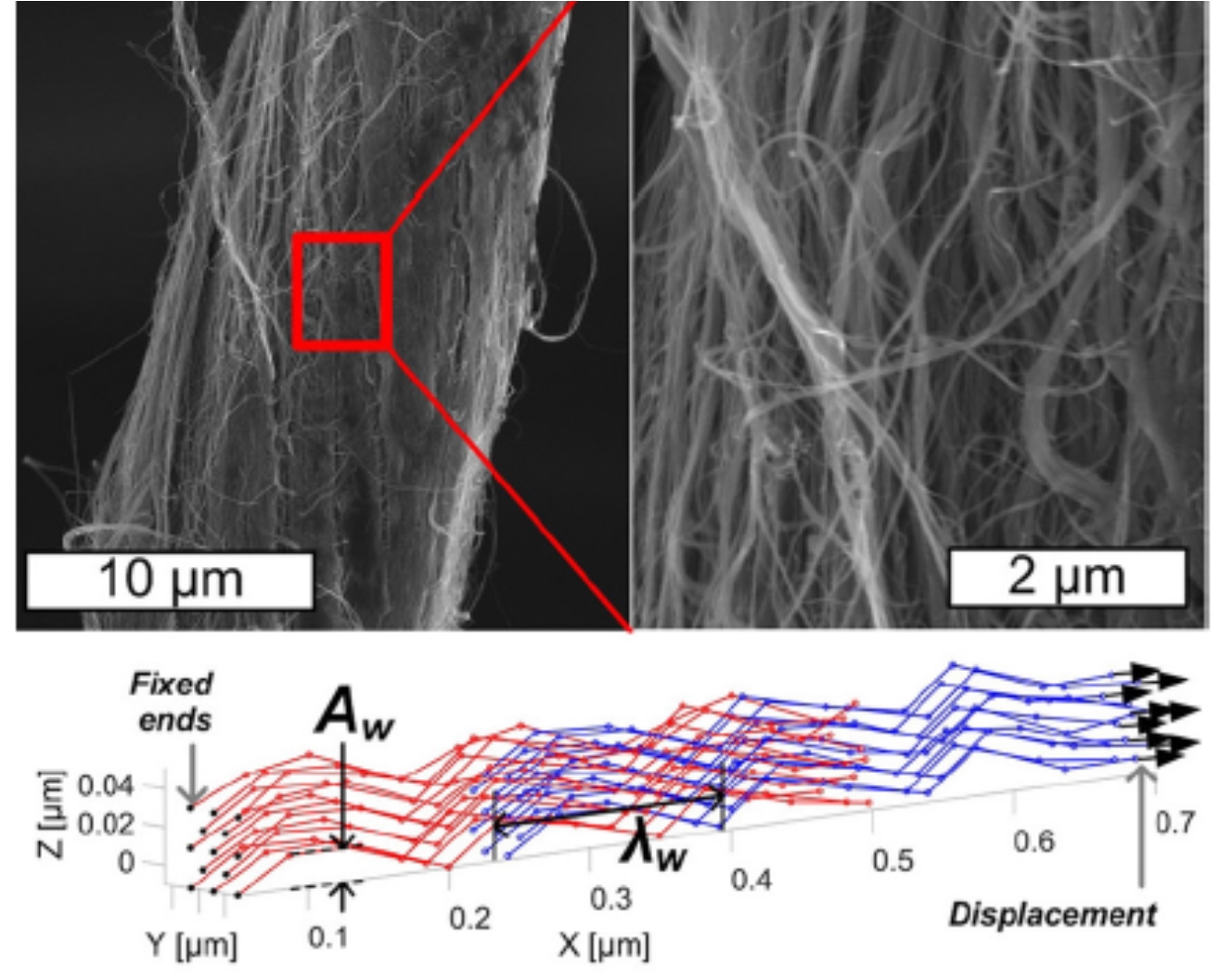

The outstanding properties of individual carbon nanotubes (CNTs) have motivated interest in CNT fibers for composite materials, high-strength conductors and multifunctional textiles. However, despite advances in manufacturing, the strength of CNT fiber remains 10–100 fold less than individual CNTs. In light of the complex, multi-scale load transfer in CNT yarns, a hierarchical model taking into consideration the morphology-dependent mechanics is necessary to understand this limitation. We present a coupled analytical and finite element model of three-dimensional morphology and the full tensile behavior of CNT yarns. By incorporating load-induced changes in morphology, simulations of yarns in tension show different load paths such as fracture-type or stick–slip failure depending on the waviness and number density of CNTs. The strength of untwisted pristine CNT yarns is shown to be limited to <10% of the intrinsic CNT strength, even at practical limits to CNT packing density and alignment. Load-induced changes in CNT morphology are verified by tensile testing of CNT yarns along with in-situ X-ray scattering. In addition, the nominal structure of the yarn is shown to strongly influence the improvement in strength achieved by densified and/or cross-linking, and a sublinear relationship between CNT contact enhancement and yarn strength is predicted. Thus, this work provides a means to investigate the complex load transfer mechanisms in CNT assemblies, and to further study the process-structure–property limits of CNT yarns.