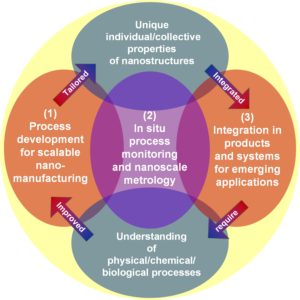

The societal impact of nanotechnology hinges on developing novel scalable nanoscale manufacturing processes and metrology techniques that can translate scientific discoveries into viable technologies. The research mission of the NanoProduct Lab (Bedewy Research Group) at the University of Pittsburgh is to bridge the gap that currently exists between promising proof-of-concept functional nanostructures (in lab-scale environment) and mass-produced products (in industry). Hence, as shown in the diagram below, the overarching goal of our research group is threefold:

- to create new lab-scale nanofabrication processes and to transform these methods to economically viable and scalable manufacturing technologies,

- to develop in situ process monitoring and nanoscale metrology techniques to enable data-driven process discovery and quality control, and

- to integrate engineered nanomaterials into functional products for emerging applications such as energy storage/transport, chemical/biological sensing and regenerative medicine.

In order to achieve the above-mentioned goals, our group primarily focuses on leveraging the nanoscale building blocks below by integrating the science and technology of nanofabrication process development with in situ and ex situ metrology/characterization, as outlined below.

Nanoscale building blocks

Advanced nanotechnology applications rely on either the unique properties of individual nanoscale building blocks or the collective properties of clusters, or large ensembles, of nanostructures in designed 2D or 3D configurations. We work on combining top-down nanofabrication with bottom-up synthesis and self-assembly of nanoscale components and biomolecular structures in order to create functional nanostructured materials. Below is a list of some nanoscale building blocks, fabrication processes and characterization/metrology techniques that we focus on in our group.

Carbon nanomaterials

The family of carbon nanomaterials currently includes zero-dimensional fullerenes, one-dimensional nanotubes and nanofibers, two-dimensional graphene sheets, and complex three-dimensional architectures. Each of these forms have unique properties and specific fabrication challenges for controllably tailoring their respective morphologies; however, there are many fundamental similarities in the atomic pathways involved in the chemical synthesis and interactions of different carbon nanomaterials.

Our work focuses on carbon nanotubes (CNTs), which you may think of as a one-atom-thick sheet of hexagonally packed carbon atoms (graphene) that is wrapped seamlessly into a tube. Depending on the direction of wrapping, different CNT chiralities exhibit different electrical properties. If the CNT has one layer, it is called a single-walled CNT (SWCNT); otherwise, it is referred to as a multi-walled CNT (MWCNT).

Inorganic nanoparticles

We also work on the self-assembly of inorganic nanoparticles made of metals, oxides and their combinations. Of particular interest to our group are plasmonic nanoparticles made of gold, silver and/or aluminum, as well as clusters exhibiting collective plasmonic phenomena. We also investigate the catalytic activity of transition metal nanoparticles that are generally supported on oxide buffers.

Block copolymers

Block copolymers (BCPs) are generally formed by covalently bonding two or more homopolymer subunits, referred to as blocks. Depending on the immiscibility between the two blocks, various nanoscale ordered structures can be achieved by self-segregation during annealing. We use well-ordered BCP nanopatterns for scalable bottom-up fabrication of functional interfaces.

Biomolecules

Considering the building blocks of living organisms at different length scales, one recognizes that proteins and protein complexes fall in the size range of 1-100 nanometers, which coincides with the length-scale of nanoengineered structures such as nanoparticle, nanotubes, and nanowires. Our groups works on exploiting this opportunity by capitalizing on the diversity of protein shapes and sizes for interfacing/integration with advanced functional nanomaterials.

Nanofabrication processes

Combining top-down fabication processes such as deposition, exposure, and etching with bottom-up synthesis and self-assembly of nanoscale building blocks.

Chemical vapor deposition

Chemical vapor deposition (CVD) is a promising nanofabrication process owing to it’s scalability, versatility, and the high quality of nanostrucutres produced by CVD. We use CVD to grow nanocarbon materials such as carbon nanotubes (CNTs). We use a combination of experimental and mathematical modeling techniques in order to study the energetics and kinetics of CVD growth of nanocarbon. Hence, we study the successive stages of the process, including catalyst preparation and treatment, catalytic activation, and catalytic deactivation.

Thin film dewetting

Solid-state dewetting of thin films is an elegant process, wherein a population of small nanoscale particles are created, typically on flat surfaces, by thermal annealing. The processes of nanoparticle formation by dewetting, also referred to as agglomeration, on flat substrates is driven by atomic diffusion at high temperatures. We use thin-film dewetting as a facile approach for creating dense populations of catalyst nanoparticles for carbon nanotube synthesis, as well as for creating other functional arrays of nanoparticles.

Directed self-assembly

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio.

Lithography

Nam libero tempore, cum soluta nobis est eligendi optio cumque nihil impedit quo minus id quod maxime placeat facere possimus, omnis voluptas assumenda est, omnis dolor repellendus.

Temporibus autem quibusdam et aut officiis debitis aut rerum necessitatibus saepe eveniet ut et voluptates repudiandae sint et molestiae non recusandae. Itaque earum rerum hic tenetur a sapiente delectus, ut aut reiciendis voluptatibus maiores alias consequatur aut perferendis doloribus asperiores repellat.

Nanoscale metrology and materials characterization

Nanotechnology is enabled by tools and techniques that are capable of interrogating the nanoscale to obtain quantitative information about the spatial and temporal evolution of morphology, size distribution, and properties during fabrication. We use a combination of in situ and ex situ characterization techniques and process monitoring methods.

Synchrotron X-ray techniques

Using Sychrotron X-rays for characterizing large populations of nanostructures uniquely enables interrogating millions of nanostructures simultaneously as the X-ray beam interacts with them. We focus largely on using small angel X-ray scattering (SAXS) in transmission mode for revealing the spatiotemporal evolution of carbon nanotube diameter distribution, quantified alignment, and volumetric/number density. We also use grazing incidence SAXS (GI-SAXS) to probe the formation of nanoparticle arrays on surfaces by thin-film dewetting or self-assembly. The high X-ray brilliance combined high speed data collection also enables studying fast dynamic processes in the nanoscale.

Electron microscopy and related techniques

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio.

Optical techniques and imaging

At vero eos et accusamus et iusto odio dignissimos ducimus qui blanditiis praesentium voluptatum deleniti atque corrupti quos dolores et quas molestias excepturi sint occaecati cupiditate non provident, similique sunt in culpa qui officia deserunt mollitia animi, id est laborum et dolorum fuga. Et harum quidem rerum facilis est et expedita distinctio.